Description du produit:

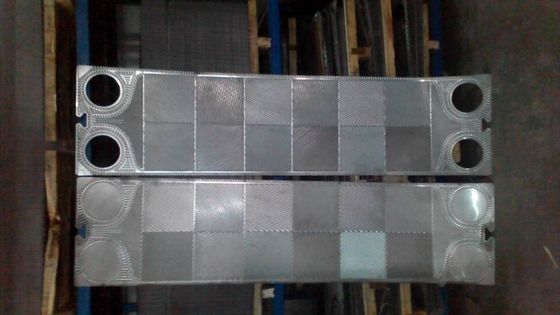

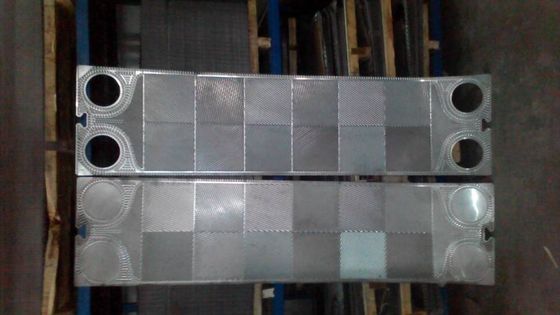

Les joints d'échangeur de chaleur à plaques jouent un rôle crucial pour assurer le fonctionnement efficace et fiable des échangeurs de chaleur à plaques dans diverses industries.Conçus spécialement pour les échangeurs de chaleur à plaques de joints, ces joints sont des composants essentiels qui aident à maintenir un joint sécurisé entre les plaques, à prévenir les fuites et à assurer des performances optimales de transfert de chaleur.Disponible en trois types distinctsCes joints offrent des solutions polyvalentes adaptées aux différents besoins d'installation et de maintenance.

Les joints d'échangeur de chaleur sont conçus pour résister à des conditions de fonctionnement difficiles, ce qui les rend idéaux pour un large éventail d'applications.Les joints sont conçus pour fonctionner sous une pression maximale de 3.0 MPaG, équivalent à 30 bar, avec une pression nominale allant jusqu'à 25 bar.Cette tolérance à la pression robuste garantit que les joints conservent leur intégrité et leurs propriétés d'étanchéité même dans des environnements à haute pression, protégeant le système d'échangeur de chaleur contre les dommages éventuels et les défaillances de fonctionnement.

L'une des caractéristiques clés de ces joints d'échangeur de chaleur à plaques est leur adaptabilité à différentes zones de transfert de chaleur.Ces joints sont parfaitement adaptés pour les unités d'échangeurs de chaleur de taille moyenneCette caractéristique permet des processus d'échange de chaleur efficaces, facilitant une gestion thermique efficace du chauffage, du refroidissement, de l'électricité et de l'électricité.et applications de procédés industriels.

La disponibilité de trois types de joints clip-on, glu-on et snap-on permet aux utilisateurs de sélectionner le joints le plus approprié en fonction de leurs besoins spécifiques.Les joints à pinceau sont faciles à installer et à enlever, ce qui les rend idéales pour les applications nécessitant un entretien fréquent ou le remplacement des joints.amélioration de la rétention des joints et minimisation du risque de déplacement pendant le fonctionnementLes joints à pince combinent les avantages des deux, offrant un ajustement sûr avec des procédures d'installation relativement simples.

Le remplacement des joints des échangeurs de chaleur est une tâche critique de maintenance qui garantit la longévité et l'efficacité des échangeurs de chaleur à plaques.la pressionLe remplacement rapide des joints d'échangeur de chaleur permet d'éviter les temps d'arrêt du système, les réparations coûteuses,et la contamination potentielle des fluides de procédéLes joints conçus à cet effet sont fabriqués avec des matériaux de haute qualité qui offrent une excellente résistance à l'usure, à la corrosion et à la dégradation thermique.

En outre, ces joints sont fournis avec une garantie complète d'un an, ce qui reflète la confiance du fabricant dans la durabilité et la qualité du produit.Cette garantie offre aux clients une tranquillité d'esprit, leur assurant des performances fiables et un soutien en cas de défauts de fabrication ou de défaillances prématurées. Investing in high-quality heat exchanger gaskets not only enhances system reliability but also contributes to overall operational cost savings by reducing the frequency of replacements and maintenance interventions.

En résumé, les joints d'échangeur de chaleur à plaque sont indispensables pour maintenir l'intégrité et l'efficacité des échangeurs de chaleur à plaque d'étanchéité.Leur conception s'adapte à diverses préférences d'installation grâce à un clip-on, collant et snap-on, tandis que leur capacité de manipulation de pression robuste jusqu'à 25 bar assure une performance fiable dans des conditions exigeantes.6 mètres carrés et une garantie de 1 an., ces joints représentent un excellent choix pour toute personne à la recherche de solutions fiables de remplacement des joints d'échangeur de chaleur.transfert de chaleur efficace, et prolongé la durée de vie des équipements dans de nombreuses applications industrielles.

Applications:

Les joints d'étanchéité des échangeurs de chaleur en tôle sont des composants essentiels conçus spécifiquement pour les échangeurs de chaleur en tôle à joints, garantissant des performances d'étanchéité optimales et une efficacité opérationnelle optimale.Ces joints sont fabriqués conformément aux normes strictes ISO et ASTM, garantissant une qualité et une fiabilité élevées dans diverses applications industrielles.les rendant adaptés à des environnements exigeants où il est essentiel de maintenir des joints étanches sous pression.

Le remplacement des joints des échangeurs de chaleur est une activité de maintenance courante dans les industries qui utilisent des procédés de transfert de chaleur.Ces joints jouent un rôle essentiel pour prévenir les fuites et maintenir l'intégrité du système d'échangeur de chaleurAvec une surface de transfert de 0,45 et une surface de 0,41 m2, les joints assurent une efficacité de transfert de chaleur tout en assurant un joint sécurisé entre les plaques.Cet équilibre entre étanchéité et efficacité thermique les rend indispensables dans des applications allant du traitement chimique aux systèmes de climatisation.

Dans les scénarios où les joints d'échangeur de chaleur existants présentent des signes d'usure, de dégradation ou de fuite, un remplacement rapide est crucial pour éviter les temps d'arrêt et les réparations coûteuses.Ces joints sont conçus pour une installation simple et la compatibilité avec une large gamme d'échangeurs de chaleur à plaques jointes, facilitant les opérations de maintenance rapides et efficaces.ces joints offrent des performances constantes dans des conditions de pression et de chaleur variables.

En outre, le produit est fourni avec une garantie d'un an, ce qui reflète la confiance du fabricant dans sa durabilité et sa longévité opérationnelle.Cette garantie assure une tranquillité d'esprit aux opérateurs de l'usine et aux équipes de maintenance, assurant que les joints d'échangeur de chaleur de plaque fonctionneront de manière fiable tout au long de leur durée de vie.Ces joints sont indispensables pour maintenir l'efficacité et la sécurité des échangeurs de chaleur à plaques jointes dans plusieurs industries, ce qui en fait un élément essentiel de toute stratégie de maintenance des systèmes d'échange de chaleur.

Personnalisation:

Nos joints d'échangeur de chaleur en plaque sont conçus et fabriqués selon les spécifications de la norme Globle, ce qui garantit des performances fiables dans diverses applications.45, ces joints fournissent un transfert de chaleur efficace pour vos systèmes d'échangeurs de chaleur à plaques de joints.Notre joints d'échangeur de chaleur garantissent une durabilité durable même dans des conditions difficiles.Convient pour des pressions jusqu'à 25 bar, ces joints sont idéaux pour maintenir l'intégrité et l'efficacité de votre échangeur de chaleur à plaques jointes.Nous offrons une garantie d'un an pour vous assurer de la qualité et de la fiabilité de nos services de personnalisation de produits.

Assistance et services:

Nos joints d'échangeur de chaleur sont conçus pour fournir des performances d'étanchéité fiables dans un large éventail de conditions de fonctionnement.il est important de suivre une installation correcte, les procédures d'entretien et de manutention.

Installation: avant d'installer les joints, assurez-vous que les surfaces des plaques sont propres et exemptes de débris ou de vieux matériaux de joints.Alignez soigneusement les joints sur les plaques pour éviter de se tordre ou de s'étirerUtilisez la séquence de serrage et les réglages de couple recommandés pour le modèle d'échangeur de chaleur à plaque pour éviter une répartition inégale de la pression.

Maintenance: Il est essentiel d'inspecter régulièrement les joints pour détecter les signes d'usure, de déformation ou de dommages chimiques.Il est conseillé de tenir un registre de la durée de vie des joints pour planifier les remplacements en temps opportun et minimiser les temps d'arrêt.

Manipulation et stockage: Gardez les joints dans un endroit frais et sec, à l'abri de la lumière directe du soleil, de l'ozone et des produits chimiques qui peuvent dégrader le matériau.Évitez de plier ou de plier les joints excessivement pendant la manipulationUn emballage approprié doit être maintenu jusqu'à l'installation pour préserver l'intégrité du joint.

Compatibilité: Assurez-vous que le matériau du joint est compatible avec les fluides et les températures de fonctionnement dans votre application spécifique.L'utilisation du bon type de joints permet de maintenir l'efficacité de l'étanchéité et d'allonger la durée de vie.

Assistance technique: pour obtenir de l'aide pour la sélection des joints, les procédures d'installation ou le dépannage, veuillez consulter la documentation du produit ou contacter votre représentant du service technique.Notre équipe s'engage à fournir des conseils d'experts pour optimiser les performances de votre échangeur de chaleur de plaque.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!